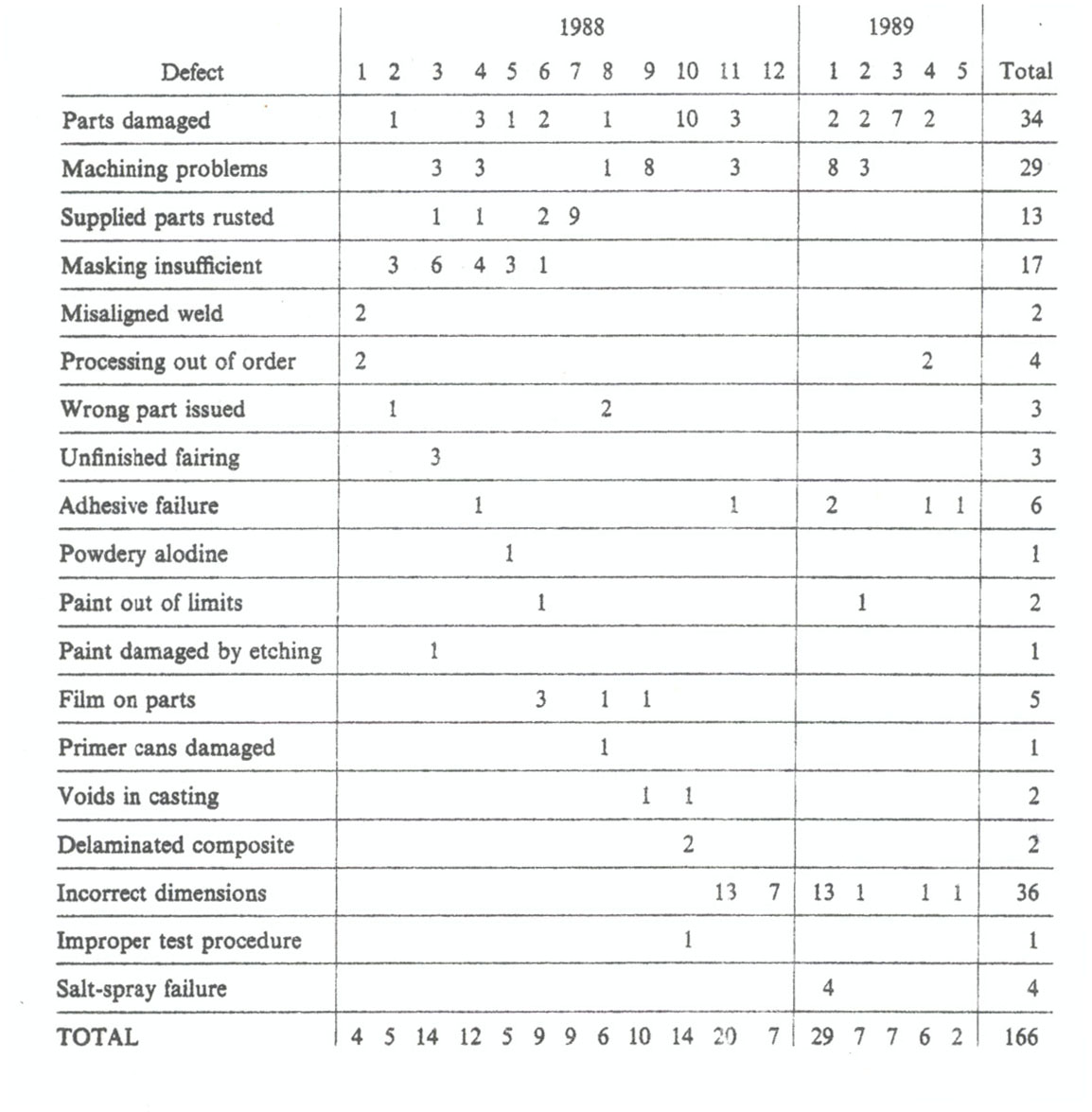

In early stage of problem solving and quality improvement, it will often become necessary to collect historical or current data about the process under investigation. A check table can be very helpful in this data collection activity. The check table shown in the following page was developed by an engineer at an aerospace firm (Hughes), in investigating the various types of defects the occurred on a tank used in one of their products with a view toward improving the process. (He originally called it check sheet. In order to avoid confusion with the other check sheet, this author changed its name to check table, keeping the original contents). The engineer designed this check table to facilitate summarizing all the historical defect data available concerning the tanks. As only a few tanks were manufactured each month, it seemed appropriate to summarize the data monthly and to identify as many different types of defects as possible.

The time oriented summary is particularly valuable in looking for trends or other meaningful patterns. For example, if many defects occur during the summer, one possible cause that should be investigated is the use of temporary workers during a heavy vacation period.

The time oriented summary is particular valuable in looking for trends or other meaningful patterns. For example, if many defects occur during the summer, one possible cause that should be investigated is the use of temporary workers during a heavy vacation period.

When design a check table, it is important to clearly the type of data to be collected, the part or operation number, date, the analyst, and any other information useful is diagnosing the cause of poor performance. If the check table is the basic for performing further calculations or is used as a work-sheet for data entry into a computer, then it is important to be sure that the check table will be adequate for this purpose before considerable effort is expended in actually collecting data. In some case, a “trial run” to validate the check table layout and design may be helpful.

A check table to record defects on a tank used in aerospace application.

DEFECT DATA FOR 1998-1989 YTD

Part No.: TAX-41

Location: Bellevue

Study Date: 6/5/89

Analyst: TCB

WORKING EXAMPLE

Create a check table for the production of a hydraulic value following the example in the previous page. The time period to be used is one year. Make sure to include all the necessary information.

School of Technology

College of Business & Applied Sciences

Eastern Illinois University