SIMPLE TOOLS SOLVE COMPLEX PROBLEMS

(Case Study)

Simple techniques can be used in most organizations, large or small, to solve problems in the office or factory.

BRUCE RUDIN, quality assurance manager, Rotor Clip Co., Inc., Somerset. NJ

If you're looking for a way to solve a quality/management problem, you don't have to go far. Textbooks abound with quality techniques that promise to put you on the right road to a solution. But do these methods actually work? Can they be successfully applied to everyday business/quality problems?Rotor Clip regards today's problem-solving techniques as a creative arsenal at its disposal. It enables the company, a major manufacturer of retaining rings and self-tightening hose clamps, to systematically "make war" on problems.

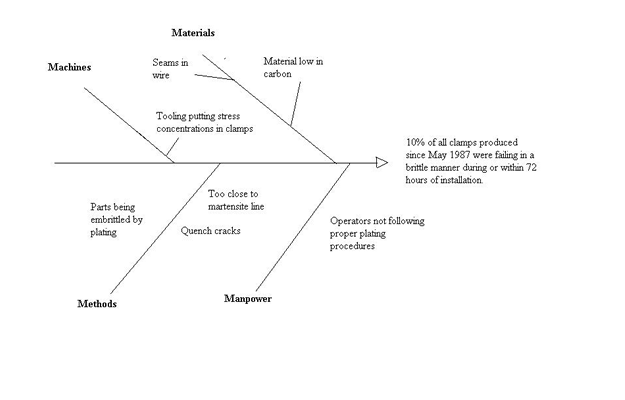

For example, two years ago one of our parts, a self-tightening, wire-formed hose clamp, was failing final inspections. Since a reason for the failures was not evident, managers and supervisors decided to use a fishbone diagram—a cause-and-effect approach—to probe for a solution.

Every employee involved with the part was called to a meeting. The first step was to express the problem in its simplest terms. After some deliberation, it was stated this way: "Ten percent of all hose clamps produced during the week of May 18, 1987, are failing in a brittle manner during stress testing at final inspection."

The next step was to draw the fishbone structure on a board and divide it into four potential problem areas: methods, machines, manpower and materials. (See Figure 1.) At this point the group was encouraged to brainstorm reasons for the problem and list them in the appropriate category.

Some simple ground rules helped make the most of this process. The group leader encouraged all members to participate. Once a point was listed on the board, the group moved on to a new idea, preventing prolonged discussion of one area or one party's monopolizing the discussion. Finally, everyone's ideas were accepted without criticism.

After reviewing all the probable causes, the group concluded that the salt temperature of the quenching tank (a heat-treating step) was too close to the martensite line. This was selected as a trial solution. Consequently, the salt tank temperature was raised, but the adjustment didn't alleviate the problem.

The group met again and agreed to pursue the second possibility, seams in the wire, as a possible cause. Wire samples from the parts that failed inspection were examined metallographically. Seams were confirmed as the major cause of the defective parts.

The suspect material was returned to the supplier and new material yielded pans that passed QA's final inspection.

Figure 1. The fishbone diagram shown here helped Rotor Clip isolate the cause of detective parts. Seams in the wire turned out to be the culprit.

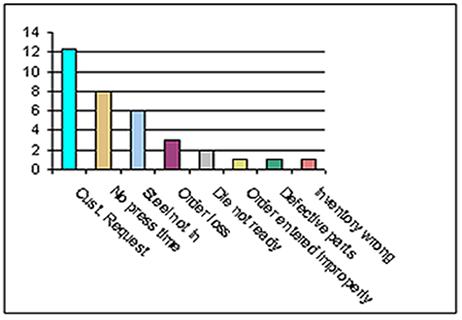

Freight chargesWhen management detected rising premium freight charges for shipping the retaining rings, it decided to monitor these costs to determine the primary cause. A Pareto diagram (Figure 2) was used to study the problem.

The main causes for premium shipments were listed on the X axis. The Y axis contained the frequency of occurrence. The study covered three months to we could collect enough data to allow to draw conclusions. The chart was filled out everyday by the person in charge of invoicing orders to ensure objectivity.

The results were startling. Customer requests made up the most frequent cause for costly premium shipments. Next was no available machine time. A m meeting was held to review these results and plan corrective action.

At the meeting, it was decided to continue the study to identify which custom consistently expedite their sipments, these customers were identified, sales would work closely with them to find ways of eliminating the problem.

Regarding machine time, once a die is installed in a stamping press, it runs until it produces the maximum number of parts (usually a million) before it's removed for routine maintenance. Although this policy results in the most efficient utilization of the tooling, it ties up the press and ultimately accounts for rush, premium shipments. We decided to revise this practice and limit die runs to three-month requirements to fill orders more efficiently.

Advertising department

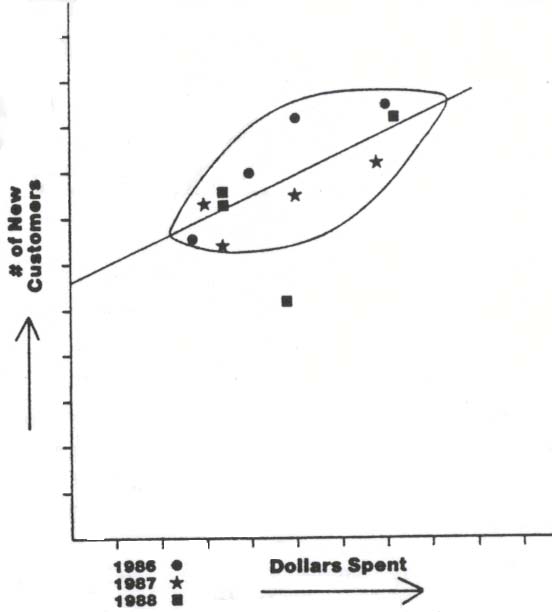

Problem-solving techniques also have been applied successfully by our advertising department. Traditionally, it is difficult to prove the effect of advertising expenditures on the bottom line. Specifically, Rotor Clip's management wanted to learn if the amount of advertising dollars spent correlates with the number of new customers gained in a given year. Since the amount of money spent varies from quarter to quarter, does the number of new customers vary accordingly? A scatter diagram was selected as the best method of determining this.

Advertising dollars spent by quarter were plotted against the number of new customers added for the same period. This was done for all four quarters in each of the last three years (1986, 1987 and 1988).

The results (Figure 3) show that quartters with the heaviest advertising expenditure saw the largest numbers of new customers added to the list. This was fairly consistent for all quarters except for the second quarter of 1988, an outlier that clearly stood out from the rest. Advertising checked the media schedule and discovered that experimental image ads dominated that particular period, perhaps accounting for the decrease. As a result, this point was eliminated from the data.The correlation was calculated to be r =0.78, a figure that shows the significance of the dollars spent.

The scatter diagram also prompted the advertising department to eliminate image ads from its schedule. These tend to draw lower response rates and, according to the study, fewer actual customers. The standard "shopping can" ad, which has dominated the company's advertising program for the past several years, appears to produce the best results. Other techniques are planned to determine which trade publications and types of ads produce the most customers.

Rotor Clip's successes with these methods can be repeated in virtually any organization, large or small. The techniques are simple and can be applied to any problem arising in the office or on the factory floor. This way of analyzing data offers a sound basis on which to make decisions about your company and its future direction.

School of Technology

College of Business & Applied Sciences

Eastern Illinois University